Acceptance opinion of environmental protection for technical renovation project of electronic energy saving and environmental protection chip of cork

In January 4, 2018, Shandong Kexin Electronics Co., Ltd. established the inspection and acceptance working group, and completed the environmental protection acceptance of the company's "energy saving and environmental protection rectifier chip technology transformation project". The working group on behalf of the acceptance by the construction unit - Shandong branch core Electronics Co. Ltd, environmental impact assessment of Ji'nan City Environmental Protection Agency - Planning and Design Institute, and acceptance report of organization - Shandong Green monitoring of Limited by Share Ltd and 3 professional technical experts (list attached). The acceptance team strictly checks and approving the project in accordance with relevant national laws and regulations, technical specification for completion of environmental protection and acceptance of construction projects, environmental impact statement of the project and approval decision of approval department. Inspection group listened to Shandong Kexin Electronics Company Limited on the project and the implementation of environmental protection and introduction of Shandong Green Limited by Share Ltd on monitoring project completion and acceptance of environmental protection monitoring is introduced, on-site inspection of the operation of construction, engineering and environmental protection facilities, review and verify the relevant information. After careful discussion, the following acceptance opinions are formed.

First, the basic situation of the construction of the project

(1) The content of the construction site, scale, main construction and investment

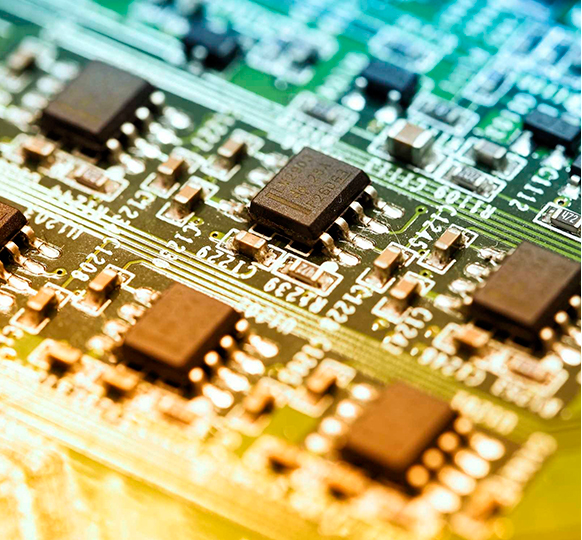

Construction project: energy saving and environmental protection type rectification chip project;

Construction unit: Shandong Corson Electronics Co., Ltd.

The nature of the project: technical reform;

Construction site: the east side of the middle section of the Ming Port Road in Zhangqiu district;

Total investment: 12 million yuan, of which 1 million yuan for environmental investment;

The number of workers: the original 300 people, this technical reform does not add staff.

Working hours in the year: three class system and 360 days of working time.

After the completion of the technical renovation project, the annual production chip is 6 million pieces per year, of which the diffusion chip is 5 million 760 thousand pieces per year, and the GPP wafer is 240 thousand pieces per year.

(two) construction process and environmental protection examination and approval

The project in December 2013 by the Ji'nan municipal environmental protection planning and Design Institute prepared "Shandong branch core Electronics Co., energy saving and environmental protection type rectifier chip project environmental impact report form", and Zhangqiu District Environmental Protection Bureau EIA approval on 03 2014 14 July (Zhang Huan report 2014 No. 2) according to the "construction projects; completion of the environmental protection acceptance management measures", Shandong Kexin Electronics Co. Ltd. in September 2017 commissioned by the Shandong Limited by Share Ltd Green detection project overall acceptance. After the inspection of Limited by Share Ltd in Shandong, Green commissioned the organizing technician to investigate the scene, and compiled the acceptance monitoring plan of Shandong Ke Xin Electronics Co., Ltd., which is energy saving and environmental protection rectification chip technology transformation project. It was checked on site on ~18 September 17, 2017.

(three) the scope of acceptance

The acceptance of the project by the main project, auxiliary engineering, public engineering, environmental engineering, the scope of acceptance for the project approved by the EIA and the related content, involving noise, solid waste pollution prevention and control facilities, to the local environmental protection department approval or approval opinions.

Two. The change of the project

Through on-site investigation, comparison with EIA reports and approval opinions, the project is a technological transformation project. The contents of actual construction are inconsistent with the contents of EIA and approval.

1, the number of main production equipment diffusion furnace changes. The EIA approved 5 new production equipment diffusion furnaces and 4 new production equipment diffusion furnaces, and the enterprise promised not to increase the remaining 1 diffusion furnaces.

2. Changes in domestic sewage treatment facilities. The environmental assessment requires the construction of domestic sewage treatment facilities; the actual sewage is treated into the life pipe network after the disposal of the septic tank.

3, the location of the waste gas treatment facilities has changed. The EIA report waste gas treatment facility is on the ground. The actual waste gas treatment facility is moved from the ground to the top of the plant.

The above is not a major change, as compared with the [2015] 52.

Three. The construction of environmental protection facilities

(1) waste water

The waste water produced in the production process of the project is divided into production wastewater and domestic sewage. Production wastewater is mainly composed of acid and alkaline wastewater, fluoride containing wastewater, sand blown wastewater, cleaning wastewater which can not be reused in various processes (general clean wastewater), cleaner cleaning waste water and pure water station wastewater.

During the production process, all kinds of waste water generated from each section of the production line were collected from the sewage collection network of the factory area to the production wastewater treatment station. The cleaner waste water was reused after purified by pure water plant, and the domestic sewage was discharged after septic tank treatment. The production wastewater and domestic sewage pipe network are discharged into the first sewage treatment plant in Zhangqiu district for further treatment.

(two) exhaust gas

1) organized waste gas

Particulate waste gas: from the sand blowing process in No. 3 workshop, the main pollutants are particles, after treatment with pulse dust removal facilities, 1 15m high exhaust gas cylinders are discharged.

Acid and alkali waste gas is mainly derived from various acid-base core treatment processes, including pretreatment process, diffusion process and GPP production process. The main pollutants are fluorides, sulphuric acid fogs, HCl, NH3, NOx and so on. The acid and alkali waste gas was collected by the collecting hood of the filler spray layer (alkali spray) respectively, and then discharged through 2 exhaust cylinders (No. 3 workshop exhaust chamber height 17m, 4 workshop exhaust tank height 15m).

Organic waste gas: from isopropanol dehydration, photolithography and passivation, the main pollutant is non methane total hydrocarbon. The organic waste gas is collected by a workshop gas collector and then discharged by a 15m high exhaust gas cylinder after the photocatalytic oxidation treatment.

Canteen fumes: the factory has a canteen with natural gas to provide food for the staff of the factory. The oil fume exhaust is discharged by the 1.5m exhaust of the roof after the oil fume purifier (manufacturer: Beijing Jingbo Huaxing environmental protection equipment Co., Ltd.).

(2) unorganized exhaust gas

Unorganized exhaust gas is the unorganized exhaust gas generated during the storage process of all production processes and various raw and auxiliary materials. The main pollution factors are particulate matter, NOx, fluoride, sulfuric acid fog, hydrogen chloride and non methane total hydrocarbon.

(three) noise

The main noise source of the technical renovation project is the air compressor, the fan and the sand blowing machine. The air compressor and air blower are located outside, and the sand blowing machine is located in the workshop. The noise reduction measures, such as basic vibration isolation and vibration isolation, indoor layout and building noise reduction, are adopted.

(four) solid waste

1) hazardous waste: hazardous waste generated during the project operation is the main waste heat conductive oil furnace used in the process of every 5 years, waste heat conducting oil in hazardous waste collection commissioned after the temporary place Shandong renewable environmental services limited disposal.

2) general solid waste:

The solid waste produced by the project is divided into hazardous waste and general solid waste. Hazardous wastes include waste acid, nickel waste, waste photoresist, waste developer, waste fixing solution, waste isopropanol, waste packaging, etc. the general solid waste mainly includes sewage treatment station sludge, unqualified wafers, waste sand, domestic garbage and so on.

The collection of hazardous wastes is placed in the temporary storage room. The hazardous waste temporary storage has already done anti-seepage and posting marked signs of hazardous waste and classified labels, and formulated detailed hazardous waste management system, entrusted to Shandong Ping Fu Environmental Services Co., Ltd. to deal with it.

Unqualified single crystal is recycled by the chip manufacturer. Waste sand, garbage by the sanitation department timely removal, harmless treatment.

(five) other environmental protection facilities

1. the total plant construction of 160 m3 accident wastewater collection pool to ensure that the waste water under abnormal conditions is collected and properly handled.

2., the health protection distance of the project is within 50 meters. There are no environmental sensitive buildings such as schools, housing and so on. The nearest sensitive target for the project is the Ji'nan traffic advanced technology school on the west side of 70m.

3, enterprises have established and improved the environmental management system, formulated the emergency plan of Shandong Ke Xin Electronics Co., Ltd., and put it on the Environmental Protection Bureau of Zhangqiu District, Ji'nan, with the record number: 37081-2017-0126-L.

Four. Monitoring results of environmental protection facilities

(1) production conditions during the monitoring period

During the monitoring period, the production is normal, the working condition is stable, and the production load is more than 75% (the two day monitoring production load is 90%), which meets the requirements of acceptance monitoring technology specification.

(two) the discharge of the pollutants to the standard

1. Exhaust gas

During the monitoring period, No. 3 workshop pH exhaust cylinder outlet NOx, fluoride, ammonia maximum emission concentration were 5mg/m3, 0.72mg/m3, 2.49mg/m3, the maximum emission rate were 0.081kg/h, 0.011kg/h, 0.040kg/h; 4, pH of the exhaust gas outlet tube workshop in NOx, fluoride, ammonia, hydrogen chloride, sulfuric acid mist maximum the emission concentration were 6mg/m3, 0.46mg/m3, <0.2mg/m3, 1.85mg/m3, <0.2mg/m3, NOx, fluoride and ammonia, the maximum emission rate were 0.189kg/h, 0.015kg/h, 0.059kg/h. The monitoring results all met the requirements of the "comprehensive emission standard for air pollutants" (GB16297-1996) table 2, two level standard and "odor pollution discharge standard" (GB14554-93).

During the monitoring period, maximum emission concentration of 3 particles of sand blowing workshop exhaust tube in the export of 5.3mg/m3, the maximum discharge rate of 0.058kg/h, to meet the integrated emission standard of air pollutants "(GB16297-1996) table 2 grade two standard and" integrated emission standard of air pollutants in Shandong province "(DB37/2376-2013) table 2 key control area requirements.

During the monitoring period, the maximum emission concentration of non methane total hydrocarbons in the outlet of organic waste gas in workshop No. 4 is 7.13mg/m3, and the maximum emission rate is 0.052kg/h, which meets the standard requirements of "two levels of air pollutants comprehensive discharge standard" (GB16297-1996) table 2.

During the monitoring period, the maximum average emission concentration of cooking oil fumes in the outlet of the cooking fume purifier was 0.47mg/m3, which met the "small scale limit" requirement of "cooking oil smoke emission standard" (DB37/597-2006) 2.

During the monitoring period, the maximum emission concentration of unorganized gas particles, NOx, fluoride, hydrogen chloride, sulfuric acid mist, non methane hydrocarbons were 0.341mg/m3, 0.060mg/m3, <9, <0.005mg/m3, <0.02mg/m3, 10-4mg/m3 * 1.22mg/m3, meet the "integrated emission standard of air pollutants" (GB16297-1996) table 2 unorganized emission concentration limits.

2. Waste water

During the monitoring period, total production wastewater discharge port (sewage treatment station exit water) the maximum daily mean values were: pH between 7.49~7.83, CODcr was not detected, ammonia nitrogen and suspended solids 6mg/L, total phosphorus 0.12mg/L, salt 534mg/L, nickel was not detected, the monitoring results have reached the "Shandong province Xiaoqing River Basin water pollutants discharge standard" (DB37/656-2006) table 4 key protection area standards, quality supervision standard No. [2011]35 Lu, Lu [2014]7, standard of quality supervision "electroplating pollutant discharge standard" (GB21900-2008) requirements in Table 2 emission limits.

During the monitoring period, the maximum daily average value of nickel exported to nickel plating workshop is 0.016mg/L, and the monitoring results meet the emission limits specified in Table 2 of electroplating pollutant discharge standard (GB21900-2008).

Sewage is discharged to municipal sewage pipe network after treatment by septic tank, which is not monitored.

3. Noise

During the monitoring period, monitoring point boundary noise monitoring value in daytime 52.6dB (A) ~58.2dB (A), night monitoring value in 44.3dB (A) ~48.8dB (A), the monitoring results are consistent with the "industrial enterprise environmental noise emission standards" (GB12348-2008) of 2 functional areas (A), day 60dB night 50dB (A) standard.

4. Measures for discharge, disposal and comprehensive utilization of solid waste

The solid waste produced by the project is divided into hazardous waste and general solid waste.

Hazardous wastes include waste acid, nickel waste, waste photoresist, waste developer, waste fixing solution, waste isopropanol, waste packaging, etc. the general solid waste has sewage treatment station sludge, unqualified wafers, waste sand and domestic waste.

Hazardous wastes such as waste acid, nickel waste, waste photoresist, waste developer, waste fixative, waste isopropanol and waste package are entrusted to Shandong Ping Fu Environmental Services Co., Ltd. to deal with. At present, hazardous waste is temporarily stored in the temporary storage room.

Unqualified single crystal is recycled by the chip manufacturer. Sewage treatment plant sludge, waste sand, waste by the sanitation department timely removal, harmless treatment.

Five. The conclusion of the acceptance

1. The review of environmental protection and the complete examination and approval procedures at the early stage of the project construction.

2, the main body of the project and the environmental protection facilities, etc., are completed in accordance with the requirements of the EIA, and have no major changes and have normal operating conditions.

3. The main pollutant discharge of the project meets the requirements of the EIA approval standard.

4. During the project construction and trial operation, there are no environmental complaints, illegal or penalized records.

To sum up, the environmental protection procedures of Shandong core Electronics Co., energy saving and environmental protection type rectification project project chip already complete, basic technical information is complete, the implementation of environmental impact assessment and the "three simultaneous" management system, the basic implementation of the various environmental pollution prevention measures and the EIA report approval specified, all kinds of pollutant discharge standards and to achieve meet the total management requirements, in line with the completion of environmental protection acceptance conditions. According to the "Interim Measures for environmental protection construction project completion and acceptance" (China ring EIA No. [2017]4) regulations, noise and solid waste environmental protection facilities by the Zhangqiu Environmental Protection Bureau approval or approval given according to the scene, the project can be formally put into production operation.

Six, suggestions and requirements

1. Set the sampling platform and sampling port according to the standard.

2, standardizing the discharge port, doing well the operating table of the environmental protection facilities to ensure the stable operation of the environmental protection facilities.

3, strengthen the company's environmental risk management, improve the environmental risk identification, environmental risk detection and management, to ensure environmental safety. We should further improve the emergency plan for environmental emergencies, implement environmental risk prevention measures, conduct regular environmental emergency drills, and improve the ability to deal with unexpected environmental risk events.

4, strengthen the control of the related noise sources to ensure the emission of the noise in the factory.

5. The inspection and monitoring report should refine the content of monitoring quality control.

6, strengthen the daily maintenance and management of all kinds of environmental protection facilities, ensure the normal operation of the environmental protection facilities, and discharge all the pollutants in a long-term stable manner. In case of environmental protection facilities being overhauled or shut down, we should report to the local environmental protection department in time, and record them for reference.

Acceptance Working Group

January 4, 2018